Repost from Bill Moyers & Company

America’s Exploding Oil Train Problem

by John Light, September 2, 2014

If you reside in the US, there’s around an eight percent chance that you live in an oil train’s blast zone. And there’s a fight going on at the state and federal levels, between monied interests and regulatory agencies, over efforts to ensure that these trains — which have shown a tendency to burst into flames — will be relatively safe.

The increased use of hydraulic fracturing — fracking — has made oil that was previously inaccessible available to drillers. The crude then has to make its way to refineries, and while the boom in pipeline projects has received quite a bit of attention, roughly 60 percent of it travels by rail.

On Friday, California legislators passed a bill that would require railroads to tell emergency officials when oil trains filled with explosive Bakken crude — oil from a particularly productive region in western North Dakota — would pass through the state. The law reflects growing concern, across America, about the dangers of these trains moving through dense communities, including Sacramento, California’s capital.

Oil tanker cars move along a web of routes that crisscross the United States. In 2013, about 400,000 cars made the journey, a 4,000 percent increase over the previous five years. The boost in oil cars has been so great that less lucrative industries are having trouble finding rail transport for their products. In March, General Mills announced that it had lost 62 days of production on such favorites as Cheerios because the trains that had shipped agricultural products were being leased by the fossil fuel industry.

Most oil reaches its destination without any problems, but as production has skyrocketed, the railroads have become increasingly taxed. Those who live near railways have noticed the uptick, with trains rumbling through towns much more frequently, and at much higher speeds.

Last July, a tanker train filled with North Dakota crude derailed in the middle of the night in Lac-Mégantic, a small Canadian town near the border with Maine; the resulting inferno killed 47 people. Since then, derailments in Casselton, North Dakota, and Lynchburg, Virginia, have led to evacuations. The Lac-Mégantic disaster spurred protests from fire chiefs and town officials who said that they were ill-equipped to deal with a possible derailment.

In the year since, officials have moved to formalize several safety measures. This July, the Obama administration proposed a plan that involves banning certain older tank cars, using better breaks on car, restricting speeds and possibly rerouting trains.

That first point, phasing out old tank cars, is a key area of contention. For the most part, the opposition isn’t coming from the railroads; it’s the oil companies that lease the tank cars that are fighting the new regulations. As Bloomberg Businessweek’s Matthew Philips explained earlier this summer:

It’s helpful to understand the three industries with something at stake here: railroads, energy companies, and tank-car manufacturers. The railroads own the tracks but not the tank cars or the oil that’s inside. The oil often belongs to big energy companies such as refiners or even trading firms that profit from buying it near the source—say, in North Dakota—and selling it elsewhere. These energy companies tend to lease the tank cars from large manufacturing companies or big lenders such as General Electric (GE) and CIT Group (CIT).

Although it is never their oil on board, the railroads usually end up in the headlines when something goes wrong. That’s why they have been eager for a rule to make energy companies use stronger tank cars. Meanwhile, the oil industry has been busy issuing studies trying to prove that the oil coming out of North Dakota is safe enough to travel in the existing tank cars. The energy lobby also thinks railroads need to do a better job of keeping the trains on the tracks. Tank-car manufacturers, meanwhile, simply want some clarity around what kind of cars they need to build.

Canada, following the Lac-Mégantic disaster, announced plans to phase out one older tank car that has been linked to several accidents over the next three years; the Obama administration proposal would do it in two.

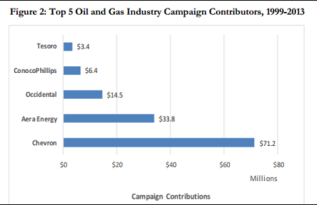

But the oil industry doesn’t want that. Leading the charge is the American Petroleum Institute, an organization that, so far in 2014, has spent $4 million lobbying regulators and Congress. They’ve pushed back against labeling Bakken crude as more hazardous than other crude oil, even though many studies have found that it is.

Environmental groups blame this lobbying effort for several weaknesses in the proposed rules. For one, they would only apply to trains that have 20 or more carloads of Bakken crude. “If the rule is approved as drafted, it would still be legal to transport around 570,000 gallons (the equivalent of the fuel carried by seven Boeing 747s) of volatile Bakken crude in a train composed of 19 unsafe, [aging] tank cars—and none of the other aspects of the new rules, including routing, notification, train speed, and more would apply,” wrote Eric de Place of the sustainability think-tank Sightline Institute, who also criticized the proposal for not immediately banning older tankers.

And even if the regulations were to be put in place despite the API’s attempts to weaken them, there’s the distinct possibility that regulators will fall short. The government has often taken a hands-off approach in determining what gets shipped, and how — and in enforcing existing rules requiring that officials in the cities it passes through be informed that potentially hazardous shipments are coming. In These Times reported that government inspections to make sure railroads are properly labeling the product they are shipping (the Bakken crude was improperly labeled in the Lac-Mégantic disaster) are supposed to be unannounced, but are sometimes pre-arranged. Meanwhile, railroads are cutting back on the number of crew members manning trains, a move that some workers feel will lead to less safe travel.

“No one would permit an airliner to fly with just one pilot, even though they can fly themselves,” wrote John Previsich, the president of the Sheet Metal, Air, Rail and Transportation union’s transportation devision. “Trains, which cannot operate themselves, should be no different.”

may surprise you.

may surprise you.

You must be logged in to post a comment.